Innovation and product responsibility

Innovation and development

We are committed to and promote innovation in the organization as an important factor in driving development in all aspects, including knowledge, skills, and learning new things. By working together with all parts of the organization through the OKR performance measurement tool, innovation and organizational development are two aspects that must work together to be strong and sustainable in a rapidly changing market. The organization is committed to continuously developing innovation for opportunities and sustainable success. The Company has the following innovation operations in 2024:

15 Exceptional Innovative Works

Transportaion System Innovation

It is a tracking of the status of goods transport from the warehouse to the customer through the company's Intranet system, facilitating the recording of shipping information. It facilitates the recording of delivery information, allowing drivers and warehouse staff to load information more easily and systematically.

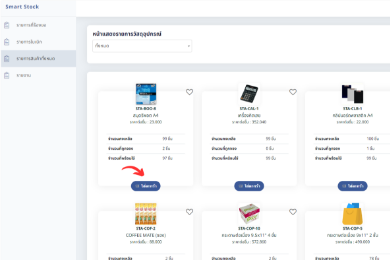

Smart Stock Innovation

The Technology Support Department has enhanced the office's equipmentwithdrawal method to make it more convenient and efficient. It functions similarly to an online trading platform, such as picking things to add to the cart and pushing withdraw to initiate the automatic withdrawal and deduction process, as well as assisting the purchasing departmentwith delivery.

Innovation, Machinery Inspection System, Engineering

A system for checking equipment and machiney within the factoy through the use of TA BLET devices or portable computers, increasing con enience for employeeswiho wallik to check the machiney by scaming the OR-Code, they will find an inscection foloon and can check according to the topic and altach image fles in case the machinew is darraged, which has a positive impact on hheh environment and economy by reducing the use and cost of paper, increasing the accuragy of data,

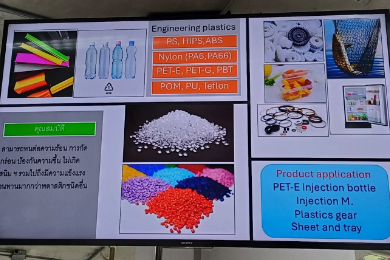

Innovation of laboratory information tracking display

Facilitate the dissemination of news or knowledge throughout the department. The system administrator can create data in the form of a file, slide, image file, knowledge, or news distribution to be displayed on the display screen by uploading it to the sy stem or er the Intranet.

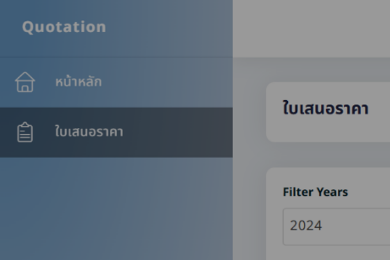

Innovation Quotation System

It faciltates sales and customer service departments to approve and send quotations to customers automatically, convenienty and quicky , and can easily search for past history in the Intranet system.

Vendor Managed Inventory (VMI) Innovation

Develop the purchase order data into the organization's intranet oy stem so that sellers can control the list of products received from the order.

Black Masterbatch Innovation for lamination

Innovation in design and production of black plastic masterbatch for lamination to obtain better properties, meet custorner needs, and expand products and generate sales for the organization.

Innovation in formula adjustment to reduce adjustment

Develop formula adjustments by using pigigment groups can be used in formulas to reduce reruns or repett ons and reduce adjustments (4 djust to increase error prevention in the work and reduce the chance ofwaste in the production process.

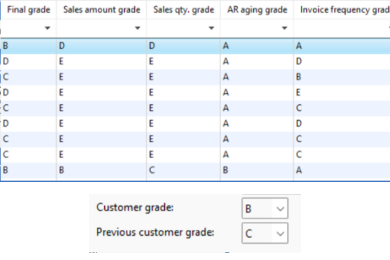

Grading Customers Innovation

Develop a system for maintaining existing and new customer bases, including a system for accessing information, evaluating customers and responding to their needs, and quickly analyzing and solving customer problems.

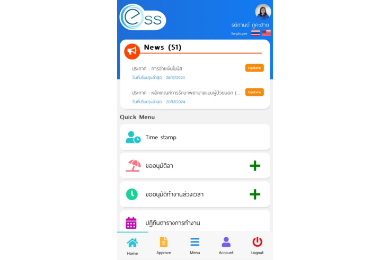

Centralized notification system in Intranet system

Enhance the notification system in the intranet to support the use of various existing programs so that approvals or important information tracking are not missed for all users involved in the process.

Innovation Application in life

Innovation for employees by using the potential of technology development to benefit employees systematically within the organization, increasing communication efficiency systematically, developing knowledge of using applications in communication, and allowing employees to access personal information and public relations for the organization conveniently.

Innovation Online Quotation

Modify the approval procedure to be done using the Intranet system under the Quotation System topic rather than utilizing the previous process, as follows: Online Approval Process: 1. Approve the quotation directly through the intranet system. 2. Send E-MAIL to the customer: The system can send the quotation to the customer via E-MAIL as soon as it is approved. There's no need to print or scan materials. 3. Instantly obtain information: You can easily recover approved quotations from the Intranet system, cutting work stages, saving time, and making document management easier.

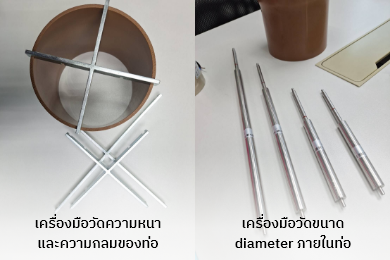

Innovation in pipe size measuring tools

The purpose is to create a HIPPO pipe measurement tool that can measure quickly, correctly, and cover all essential parameters, solving the problem of the old instrument, which is difficult to use and inconvenient. This revolutionary equipment can accurately measure size, roundness, and thickness in a matter of seconds, ensuring that every pipe fulfills the customer's specifications.

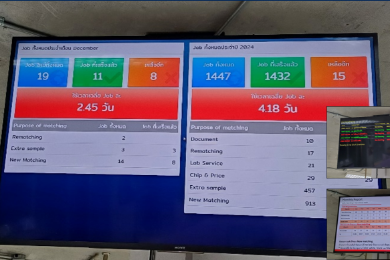

Laboratory department performance reporting system via TV Dashboard

The purpose is to enhance the real-time notification of work results to relevant parties via the central screen of the laboratory, enabling faster planning of sample delivery to customers (lead time not exceeding 4 days).

Innovation Automatic shaker machine to mix colors

It is the use of automatic paint shaker to reduce the use of human force to shake which causes fatigue and the mixed paint is 100% consistent in every piece of work.